ATP

Also known as microbial ATP bioluminescence assay or rapid hygiene monitoring

What is ATP?

ATP, or adenosine 5’-triphosphate assay, is a rapid microbial test based on bioluminescence. It is used to measure the effectiveness of cleaning activities and SSOPs performed on food-contact surfaces such as:

- Mixers

- Tanks

- Conveyors

- Piping1,2

How does it work?

The ATP test measures the presence of adenosine triphosphate (ATP) — life’s energy carrying molecule within cells. The reaction of ATP with a luciferin-luciferase complex allows the estimation of the microbial load of food samples, equipment and surfaces in direct contact with the products. Food residues, proteins and cells are rich in ATP. They undergo bioluminescence process when in contact with luciferin–luciferase where oxidation of luciferin results in light emission.1,2,3

The intensity of the emitted light is measured with a device called luminometer. The intensity is proportional to the amount of ATP produced and the level of microorganisms on the swabbed food surface. The ATP content of the sample correlates with the number of microorganisms present because all living cells have a specific amount of ATP.1,3

Application

To perform an ATP test, gather a pre-moistened swab, a food-contact surface, and an automated palm-sized bioluminescence device. Steps needed to complete an ATP assay are:

- Remove swab from device

- Swab a representative portion/area of a food-contact surface (or equipment)

- Reinsert swab into body and screw down

- Shake liquid down into bottom of clear tube and mix 2-3 times

- Insert pocket swab into the instrument or device

- Select swab site and press the run button to execute the counting or measurement

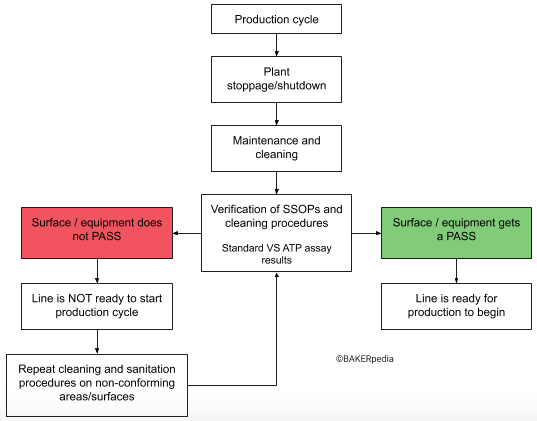

The following block diagram helps explain how the ATP test interacts with food safety systems and sanitation procedures in place in food processing facilities.

| Advantages | Disadvantages |

|

|

References

- Marriott, N.G., Schilling, M.W., and Gravani, R.B. “The Relationship of Microorganisms to Sanitation.” Principles of Food Sanitation, 6th edition, Springer International Publishing AG, 2018, pp. 33–72.

- Cramer, M.M. “Verification of Sanitation.” Food Plant Sanitation. Design, Maintenance, and Good Manufacturing Practices, 2nd edition, CRC Press, Taylor & Francis Group, LLC, 2013, pp. 167–201.

- Loughney, C.F., and Brown, S.R. “Plant sanitation.” Gracey’s Meat Hygiene, 11th Edition, John Wiley & Sons, Ltd, 2015, pp. 89–112.